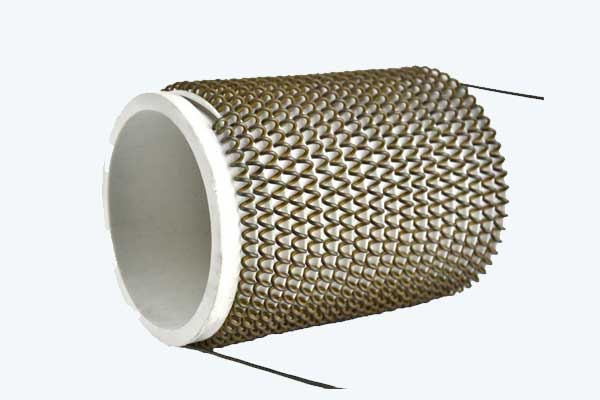

Furnace Coil Heaters are high-temperature heating elements specifically designed for use in industrial furnaces, kilns, and ovens. Made from high-resistance alloys like Kanthal (FeCrAl) or Nichrome (NiCr), these open-coil elements are wound into spiral or helical shapes and mounted on refractory ceramic supports. Their open-air coil design ensures quick heat-up, efficient heat transfer, and excellent temperature uniformity, making them ideal for continuous and high-heat applications.